|

GarraSeal 90 Asbestos Gasket SheetRecommended for steam, water, gas, salt solutions, some oils and use for pipe flanges, boiler manholes, steam engines, compressors, internal combustion engines, and pumps

GarraSeal 70 Homogenous Pure Graphite SheetA superior replacement for asbestos gaskets. It is highly chemical resistant and thermally stable.

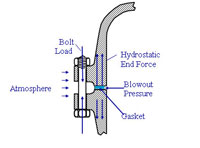

Forces Acting on a Gasketed Joint

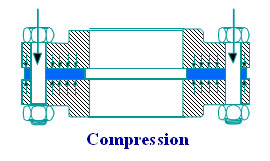

A seal is created by compressing the gasket material and causing it to flow into the imperfections of the sealing surface.

Surface Finishes (RMS)

Suggested Industry Standard

Gasket Rating Chart

For Standard ANSI Flanges

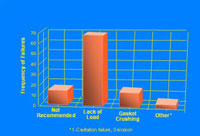

Review of 100 Gasket Failures

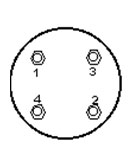

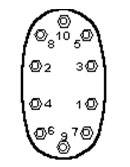

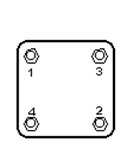

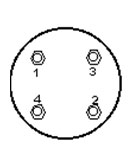

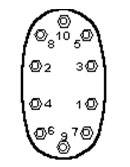

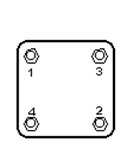

Correct Bolting Patterns

Circular Four Bolt

Non-circular Multi-bolt

Square Four Bolt

Circular Multi-Bolt

|

Product Quality

In 1975 Garlock USA through Garlock Inc. distribution Asia established Garlock Philippines Inc. to manufacture Garlock gland packings and gaskets in the Philippines. In 1983 the company was sold and the name changed to American Packing Industries Corporation, and it became a Licensee of Garlock Sealing Technologies USA.

American Packing Industries is the leading manufacturer of compressed gaskets and packings with more than 40 years experience. In 1998, it achieved its ISO 9002 Certification from SGS Yarsley International Certification Services Ltd. and migrated to ISO9001:2000 in 2003, and currently certified under ISO 9001:2008.

GarraSeals gland packings and gaskets are manufactured to the highest quality for PT. Gapura Raya by American Packing Industries Corporation.

GarraSeal Gasket

| GarraSeal Code |

30

|

60

|

70

|

75

|

90

|

95

|

| Material |

Aramid Fibre |

Carbon Fibre |

Graphite |

Graphite with Wire |

Asbestos |

Asbestos with Wire |

| Application |

Excellent compressed non asbestos gasket sheet contains high strength aramid fibers, superiors fillers bonded with high grade rubber binder which makes it suitable in general sealing applications |

High temperature non asbestos gasketing material manufactured from high grade carbon fibers bonded with quality rubber. It has an anti stick parting agent on both sides |

Flexible graphite sheet made from pure graphite without additives or binders. A superior replacement for asbestos gasket. Graphite sheet is highly chemical resistant and thermally stable. |

Anti-stick releasing agent, blended into the surface of all compressed asbestos gasketing eliminates the need for graphite sheet. All styles are excellent for severe service applications involving high pressure or high temperature. Compressed asbestos gasketing materials are especially useful where heavy flanges and high bolt loads are commonly found |

| Use |

Water

Saturated Steam

Mild Chemicals

Flange Gaskets |

steam

Hydrocarbons

Water

Oils

Gasoline and fuels

Alkilis

Coolants |

|

Heavy flanges

High bolt loads

Steam line flanges

Cylinder heads of engines

Compressors

Refrigeration equipment |

| Temperature |

382ºC (720ºF) |

+482ºC (900ºF) |

500ºC (932ºF) in air; |

540ºC (1000ºF) |

| Pressure, Max. |

1,100 psi (75.8 bar) |

2,200 psi (151.7 bar) |

2,000 psi (137.9 bar) |

3,000 psi (205 bar) |

| pH Range |

- |

|

0-14 (except strong oxidizers) |

|

| colour |

Yellow / White |

Grey |

Black |

Blue / Off White |

Grey Black / Blue |

| Thickness |

1/32", 1/16", 1/8"

0.79, 1.59, 3.18 mm |

1/32", 1/16", 1/8"

0.79, 1.59, 3.18 mm |

1/32", 1/16", 1/8"

0.79, 1.59, 3.18 mm |

1/16", 1/8"

1.59, 3.18 mm |

1/32", 1/16", 1/8"

0.79, 1.59, 3.18 mm |

1/16", 1/8"

1.59, 3.18 mm |

| Sheet size |

1.5mx1.5m |

1.5mx1.5m |

1.5mx1.5m |

1.5mx1.5m |

1.5mx1.5m |

1.5mx1.5m |

| Binder |

Nitrite |

Nitrite |

None |

None |

None |

SBR Nitrite |

|

Gaskets

Asbestos Gasketing ProductsGarraSeal 90 Asbestos Gasket SheetGarraSeal 90 is an excellent general purpose gasket. It is a compressed Chrysotile (white) asbestos fibers with SBR binder, which is fully cured. It is coated with special anti-stick release agent to…

Non Asbestos Gasketing Products

GarraSeal 60 Carbon Fiber Gasket - Nitrile BinderGarraSeal 60 is a high temperature non asbestos gasketing material manufactured from high grade carbon fibers which has been bonded with quality rubber. GarraSeal 60 is highly recommended for use in steam,…

GarraSeal 70 Homogenous Pure Graphite SheetGarraSeal 70 flexible graphite sheet is made from pure graphite without additives or binders. It is a superior replacement for asbestos gaskets. GarraSeal 70 is highly chemical resistant and thermally…

A seal is any object that is placed between two surfaces to prevent leakage. There are two basic type of industrial seals.

Gaskets : A gasket is used between two stationary objects

Packings : A packing is used between two moving objects

What is a Gasket?

A gasket is any deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.

Proper Selection

- Temperature

- Application

- Media

- Pressure

- Size

|

Temperature

- Maximum spikes

- Thermal cycling

- Continuous operating temperature (COT)

- Minimum temperatures

Application

- Flange information

- Bolting information

- Clamping force available

- Compressive stress on the gasket

|

What is an Ideal Gasket

- Shall be impervious to the fluid being handled

- Must have sufficient chemical resistance to prevent impairment of its physical properties

- Must not contaminate the system

- Must not promote corrosion of the flanges with which it comes in contact

- Must be capable of withstanding the required bolt pressure without crushing or undergoing excessive flow

- Sufficiently deformable, able to distribute the applied pressure evenly over the surfaces, compensating for irregularities

- Must be elastic enough to maintain an adequate portion of the applied load in the face of joint movement

- Must develop sufficient friction in contact with the flange surface to resist excessive creep or extrusion

- Must lend itself to easy installation and removal

Guidelines for Good Gasket Installation

- Check surface finish and flatness.

- Center the gasket on the flange.

- Tighten bolts to compress gasket uniformly. This means use a crossing pattern and tighten in multiple steps.

- Use a torque wrench, well-lubricated fasteners and hardened flat washers to ensure efficient bolt loading.

- If possible, retorque 12 to 24 hours after the initial installation.

- Never use grease-based anti-sticks or caulking compounds with the gaskets. Premature failure could occur as a result.

How Do I Choose My Gasket

- Material Compatibility

- Temperature and Pressure Resistance

- Minimize Torque Loss

- Price

- Ask Your Friendly Gapura Raya Representative

|

|

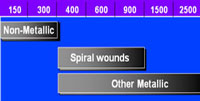

Shopping: What is Available Out There

- Rubber 200 - 400 deg F

- Asbestos 800 deg F

- Teflon 500 deg F

- Aramid 700 deg F

- Carbon 900 deg F

- Graphite 1200 deg F

|

Flex - Metallic Gaskets

- Spiral Wound Gaskets

- Bonnet Gaskets

- Ring Joint Gaskets

- Metal Jacketed Gaskets (HE)

- Serrated Gaskets

- Kammprofiles

- Metallic O-rings*

|

What is a Spiral Wound Gasket (SWG)

- Alternately winding strips of metal and soft gasket filler

- Reinforced by either an inner ring, an outer ring or both

- CR > gasket with outer ring reinforcement

- IR > gasket with inner ring reinforcement

- CRI > gasket with inner & outer ring

- BH > gasket without inner & outer ring

|

Why Use SWG

- More Complete Temperature Range - Cryogenic to +2000 deg F

- Wider Pressure Range - Vacuum to standard 2500 psi flange rating

- More Flexible / Resilient than any other Metal Gasket

- Can Be Used Against Virtually Any Corrosive Media

|

Merits of SWG Applications

- Low Cost

- Readily Available

- Good Blow Out Resistance - High Pressure Rating

- High Temperature Rating - Fire Safe

- Time Proven

|

Demerits of SWG Applications

- Inventory Problem

- High Bolt Load is Required to Effect a Seal

- High Degree of Flange Parallelism is Required

- Proper Flange Finish is Critical

- Can Damage Flange Finishing

- Large Sizes are Fragile

- Recovery is Typically Low

|

Where Do We Use SWG

Power Plant

- Steam Feed Water Pipe

- Feed Water Heater

- Valve Bonnets

- Autoclaves

|

Petrochemical

- Catalytic Cracking Plant

- Platformers

- Heat Exchanger

- Line Flanges

- Valve Bodies

|

Marine

- Boilers

- Economisers

- Main Steam Line

- Air Ejectors

|

Nuclear Plants

- Cooling Circuit Flanges

- High Temperature Gas Lines

- Pressure Vessels

- Valves

|

Critical Information

- OD of the Outer Ring / Filler

- ID of the Inner Ring / Filler

- Thickness

- Material (Ring, Filler and Winding)

- Flange Rating

- Flange Standard (ASME, JIS, ANSI, DIN)

- Quantity

Just In Case

- A leaking gasket should not be merely replaced without questioning why it leaked

- Save yourself future trouble by learning why a gasket leaks

- Remove the gasket carefully and save it

- Call your Gapura Raya representative who will check for possible clues to why the gasket leaked

- Proper installation is key to gasket performance

- Use thinnest gasket possible

- Select right gasket for the job

- PT. Gapura Raya can help install and maintain your gaskets

- PT. Gapura Raya can trouble shoot why a gasket leaked

- Choosing the right gasket will decrease down time, labor cost, fluid lost and product cost - let PT. Gapura Raya help you choose the right gasket

|

|